A Quick History and Bright Future of 3-D Printing

Would you live in a 3D printed home?

Have you ever wondered if it were possible for a 3D printer to print itself?

3D printing has been around for longer than a lot of us think, it may even be older than your grandparents! From printing extremely small and detailed parts to houses, there is an exciting future in 3D printing in just about every context.

The first known concept for what we today know as 3D printing was written in a short story by a man named Murray Leinster in 1945. In an excerpt from a passage from the story Things Pass By, he describes the general idea “But this constructor is both efficient and flexible. It feed magnetronic plastics — the stuff they make houses and ships of nowadays — into this moving arm. It makes drawings in the air following drawings it scans with photo-cells. But plastic comes out of the end of the drawing arm and hardens as it comes ... following drawings only” Although the idea of building something in 3 dimensions seems obvious now, through the 1960’s and 1970’s the idea of extruding drops of material from the end of a nozzle was new. Surprisingly this idea was brought into existence by the Inkjet company in the 1960’s and paved the way for what we know today as desktop printers that are used in homes and businesses alike. As we know, scientists and engineers are never satisfied! An individual by the name Johannes F. Gottwald had the idea in 1971 that an object made of liquified metal could be solidified in layers determined by the inject printer itself, lending to the idea that printing could certainly extend beyond the 2D world of just ink on paper. All the while Dr. Hideo Kodama was toiling away in Japan, improving and refining Gottwald’s ideas by making a special plastic responsive to temperature (a thermoset polymer) that could be used instead of metal. Since printing plastic would be able to allow for more precision in 3D prints.

Representation of Stereolithography: a light-emitting device a) (laser) selectively illuminates the transparent bottom c) of a tank b) filled with a liquid photo-polymerizing resin. The solidified resin d) is progressively dragged up by a lifting platform e) platform where first layer is solidified.

Adrian Bowyer (left) and Vik Olliver (right) with a parent RepRap machine, made on a conventional rapid prototyper, and the first complete working child RepRap machine, made by the RepRap on the left.

The 1980’s were an exciting time as the ideas for the first actual creation of a 3D printer as we know it today were beginning to take shape. The first actual use of the term “3D printing” originated in 1984, stemming from a patent filed by the entrepreneur Bill Masters. Although it wasn’t until 1987, when one of the founding fathers of SLA (stereolithography) 3D printing Chuck Hull, was able to create the first functional 3D printer. This printing technique was coined as “SLA printing” by Chuck Hull and is in reference to how the 3D prints were made in the first machine developed. The first printers made would cost upwards of hundreds and thousands of dollars and weren’t yet capable of producing the level of extreme detail we’re able to see today. It was only a matter of time, as within the next 2 decades 3D printing with the help of a community focused on sharing ideas and building upon each other’s findings exploded. It allowed research teams from bioengineers printing miniature kidneys and complex prosthetic legs to Adrian Bowyer and his team producing a self-replicating 3D printer that could print itself.

Considerable advancements in 3D printing have allowed for this technology to be used in an extremely wide range of applications, only dreamt of a few decades prior. In the medical field we have seen everything from 3D printing in dentistry to human tissue and organ cells being printing. Engineering of different polymers and materials to print has made it possible to print rubbery sponge-like material to metal and even wood particle incorporated plastics. Just as you can own a desktop printer to print 2D pictures and homework, desktop 3D printers can be used to print out just about anything you could think of, designed by others or yourself in your very own home. Thinking even larger, the idea of 3D printing has even reached the level of construction of homes and businesses. Just recently they’ve even been able to print complete homes! No matter which way you slice it, 3D printing is likely going to continue to advance into something we think may be further off in the future than it actually is. Would you want to be involved with creating and advancing these technologies?

How to get started

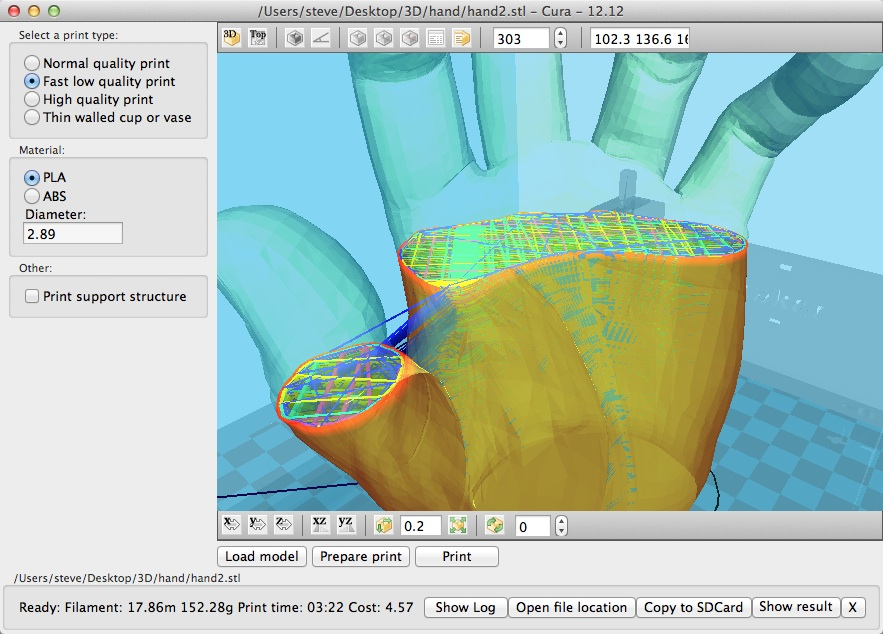

Thankfully all the recent advancements have made it extremely easy to get involved with 3D printing. The best advice I’ve seen or can give is to get involved with 3D modeling, whether it be a class at school or free software online. 3D modeling is an extremely useful skill that will be sought after and even required in most engineering fields. The ability to make and alter precise models to be used and shared among others is invaluable. Luckily for us there are tons of free CAD (computer-aided design) software’s available for all computer operating systems to learn and get familiar with. Even user-friendly ones that can be used online such as tinkercad.com, these 3D models are saved to a special type of file .stl (stereolithography file format) or .obj (3D object file format) that are interchangeable and able to be read on many kinds of CAD software. From there, your file containing your 3D image can be sent to a free “slicer” software (depicted to the right) that converts the 3D image to code called G-Code that is recognizable by the 3D printer itself. This slicing software takes the image and converts it into instructions and steps for the 3D printer to follow enabling your 3D print to come to life. If 3D printing interests you, the 3D printing community will be welcoming and encouraging for newcomers to develop and share ideas that will help benefit all of us. So, join us, as a hobby or a potential career!

Other Resources

Here are some links to other resources that may be worth checking out:

MakerBot Thingiverse for education: thingiverse.com/education

More in-depth coverage of all the kinds of different 3D printing technologies available: https://all3dp.com/1/types-of-3d-printers-3d-printing-technology/

References:

Photography is by Kamp C and Jasmien Smets

Scopigno R., Cignoni P., Pietroni N., Callieri M., Dellepiane M. (2017). "Digital Fabrication Techniques for Cultural Heritage: A Survey". Computer Graphics Forum 36 (1): 6–21. DOI:10.1111/cgf.12781.